|

What

equipment is used for etching?

Abrasive etching

equipment is still called sandblasting equipment, in spite of the

fact that sand is rarely used to etch glass anymore. However it

is not just any sandblasting equipment. Blasting equipment used

to etch glass has evolved for its specialized purpose in the past

twenty years. Compared to regular blasting equipment, the equipment

designed for glass has smaller, more easily manipulated hoses and

nozzles, special foot pedal controls, specialized lighting in the

cabinet, and other improvements.

When you are

purchasing equipment for etching glass you are much better off to

purchase it from one of the few companies who specialize in equipment

for glass. It won’t cost you much more, if any more, than equivalent

equipment used for other purposes, but it will save you hours of

time converting the other equipment for glass, not to mention the

cost in dollars to do it. Lets take a closer look.

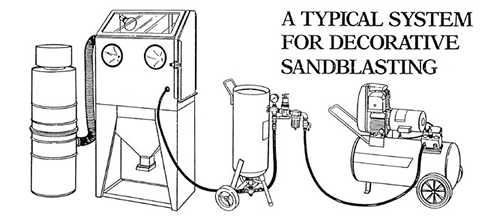

There are three major components to a glass etching setup: 1) an

air compressor (at right), 2) a sandblaster (in the middle), and

3) a blasting cabinet with dust collector (at the left). The air

compressor produces the pressurized air that powers the sandblaster

and must do so in adequate quantity for the blaster you will be

using. The blaster stores the abrasive and provides a method of

combining the abrasive with the compressed air and directing it

effectively at the glass. The blasting cabinet provides a contained

environment in which to blast, so that the spent abrasive and blasting

dust are controlled, while allowing full vision of the project being

etched.

Air

Compressors

A complete discussion of air compressors could take a whole book,

but a short introduction will have to suffice here. Compressors

are rated in terms of how much air they put out at a given pressure.

This is usually expressed something like: Output - 11 CFM (cubic

feet of air per minute) @ 90 PSI (pounds per square inch

of air pressure). These numbers are always used together, because

when one changes, the other changes as well.

You should never

buy a compressor by the horsepower because there are small consumer

compressors and large industrial compressors that have the same

horsepower rating, but which put out vastly different amounts of

air. Always buy a compressor based on how much air it puts out.

When you purchase equipment, you should get a compressor that puts

out at least 2-3 times the volume of air required by the blaster

you will be using, at the desired blasting pressure. So, you have

to know which blaster you will be using, before you buy a compressor.

Blasters

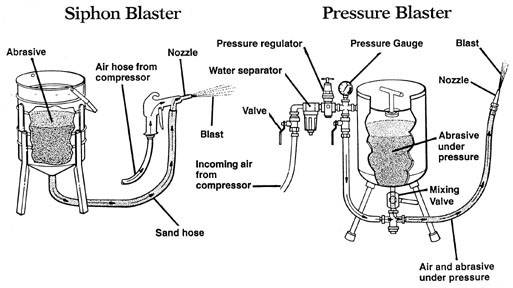

There are only two types of blasters, siphon blasters and pressure

blasters. Siphon blasters are cheaper, but inefficient and use a

lot of air. Pressure blasters are more expensive, but are much faster

and easier to use. Pressure blasters also use less air from the

compressor, which allows you to use a smaller compressor or causes

less wear and tear on an existing compressor. A standard sized pressure

blaster is not prohibitively expensive for most people, but should

be especially set up for use on glass. This means you should purchase

from a distributor who specifically configures their equipment for

glass etching. Read the specs for the blaster (nozzle size and air

requirements) to find out how much air you need from the compressor.

Blasting

Cabinets

Blasting cabinets come in all sizes and configurations. The ones

best for glass are wider and taller (with respect to their depth

from front to back), than ordinary cabinets. This accomodates flat

sheets of glass best, without requiring that the person doing the

blasting have extra long arms.

Most cabinets

allow blasting of only as large a piece of glass as will fit through

the door, so the door has to be as large as possible. However some

cabinets are especially made for larger pieces of glass and have

slotted openings in the sides and top of the cabinet, allowing large

pieces to be passed through, blasting a little at a time. Gaskets

on the moveable slots keep abrasive from getting out. These cabinets

are really your best investment because they can accomodate both

large and small pieces of glass equally well. They are the most

expensive cabinets, though.

Blasting cabinets

for glass should have incandescent, point source lighting rather

than fluorescent lights. A dust collector is essential, to keep

the dust level low enough in the cabinet so you can see what you

are blasting. Again, there are many manufacturers out there, but

only a few that set their equipment up especially for decorative

blasting on substrates such as glass.

Blast

rooms

Of course, you can build a whole blast room to blast large pieces

of glass. But that means you have have space for it in your shop

(most blast rooms are at least 8' long x 8' high x 6' deep). You

also have to equip it with a large dust collection system and a

source of clean breathing air, because you will be going inside

the room to blast. You always have to wear protective gear for your

face and exposed skin.

Equipment is

a big subject to tackle, and it is explained much more in depth

in our books and videos.

|